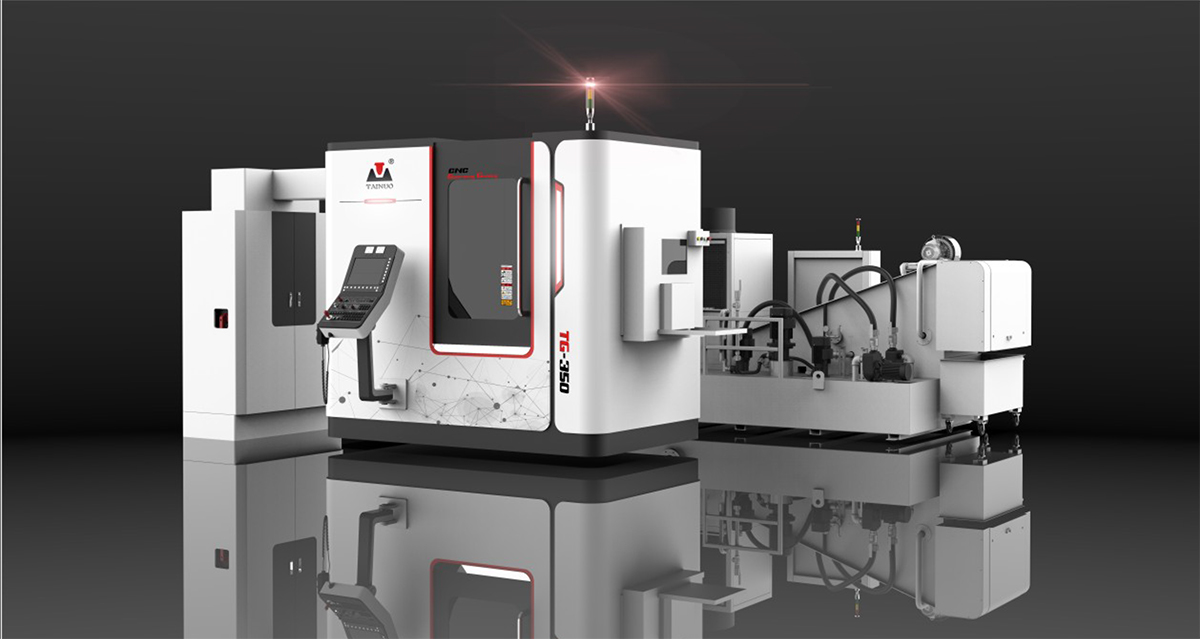

■ Introduction

● Advanced CNC supporting the precise and complex mathematical calculation

● Fine quality cast bed, 11 axes with 5 axes interpolation movement

● Torque motor table as part axis with encoder for closed loop control

● High speed and high torque grinding spindle support various machining

● Free correction of torsion grinding (Twist control grinding )

● Various advanced configuration and flexible automation solution

■ Applicable scope

Reducer gears、industry mechanical gears、agricultural machinery gears、vehicle gears and more

■ Technical specifications

| TG-350 | |

| Workpiece | |

| Max.Workpiece OD. | Ф350mm |

| Max. Module | M6 |

| Max. Helix Angle | ±45° |

| Part Table Diameter | Ф180mm |

| Grinding Parameter | |

| Spindle Nose Taper | HSK C80 |

| Max. Grinding Wheel | Φ280 × φ115 × 160mm |

| Max. Dressing Roller | Φ140 × φ52 × 40mm |

| Motion Parameter | |

| Grinding Spindle (S axis) | 23kw Max.7000rpm |

| Table Rotation (C axis) | 21kw Max.1000rpm |

| Dresser(S2 axis) | 1.7kw Max.6000rpm |

| Radial Feed (X axis) | 270mm(90-360mm) |

| Tangential Feed (Y axis) | 250mm(0-250mm) |

| Axial Feed (Z axis) | 600mm(150-750mm) |

| Tailstock (W axis) | 400mm(350-750mm) |

| Mainchine Specification | |

| Power Supply | 3AC 380V 60KVA |

| CNC system | FANUC 31i-B (11 Axes) |

| Floor Space (L×W×H) | 5320×6320x2900mm |

| Apprx. Machine Weight | 12,000kg |

簡體中文

簡體中文 English

English